Across the GCC, construction activity continues at scale—driven by mega-projects, accelerated delivery timelines, and heightened regulatory scrutiny. While Health, Safety, and Environment (HSE) remains a stated priority on most projects, incident rates often remain stubbornly high. In many cases, the issue is not a lack of safety rules, but how safety inspections are executed and documented on site.

Traditional safety walks are still widely used across GCC construction projects. However, they are increasingly failing to deliver consistent outcomes. Digital safety walks address these shortcomings by introducing structured inspection workflows, real-time evidence capture, and clear accountability—helping project teams reduce incidents and demonstrate compliance with local regulations.

Typical Safety Walk Failures on GCC Construction Sites

Safety walks are usually part of contractual and regulatory requirements, yet their effectiveness is often limited by how they are carried out on site.

In many projects, safety walks are conducted under time pressure, focusing on visible issues rather than systematic risk identification. Observations are written on paper or noted informally, then transferred later into reports—if at all. This delay increases the risk of missing details or losing context.

Another common failure is fragmented evidence. Photos taken during inspections are stored on personal devices or messaging apps, disconnected from the inspection record. When incidents occur or audits are requested, retrieving complete and reliable evidence becomes difficult.

Follow-up is also a major challenge. Unsafe conditions may be identified, but corrective actions are not clearly assigned, tracked, or verified. As a result, the same hazards often reappear across multiple safety walks—particularly on large GCC sites with several subcontractors working in parallel.

Critical HSE Focus Areas in GCC Construction Projects

Construction sites in the GCC face specific safety risks influenced by climate, workforce composition, and project scale. Effective safety walks must consistently address the following areas:

Working at height remains one of the leading causes of serious incidents, particularly during structural works and façade installation. Heat stress is a critical concern, especially during summer months, requiring regular monitoring of rest periods, hydration, and shaded areas.

Heavy equipment movement, lifting operations, and interface between pedestrians and machinery are common risk points on large sites. Temporary electrical installations, fire safety arrangements, and emergency access routes must be inspected regularly and documented clearly.

Personal protective equipment compliance, housekeeping, material storage, and permit-to-work systems are also core components of any effective HSE inspection in the region.

Local authorities in the UAE, such as Dubai Municipality, emphasize the importance of maintaining clear health and safety controls on construction sites, supported by proper inspection records and documentation.

Similarly, in Saudi Arabia, occupational safety requirements are increasingly formalized under national frameworks overseen by Ministry of Human Resources and Social Development, reinforcing the need for structured and traceable safety inspections across major projects.

Why Traditional HSE Inspections No Longer Work at Scale

Paper-based or informal inspections struggle to support the complexity of modern GCC construction projects. When safety data is spread across notebooks, emails, spreadsheets, and messaging platforms, it becomes almost impossible to identify patterns or address root causes.

Without a central system, safety walks become isolated events rather than part of a continuous safety management process. Lessons learned on one site are rarely transferred to others, and recurring risks are not systematically addressed.

As projects scale in size and complexity, this fragmented approach increases exposure to incidents, delays, and regulatory scrutiny.

How Digital Inspection Workflows Strengthen HSE Performance

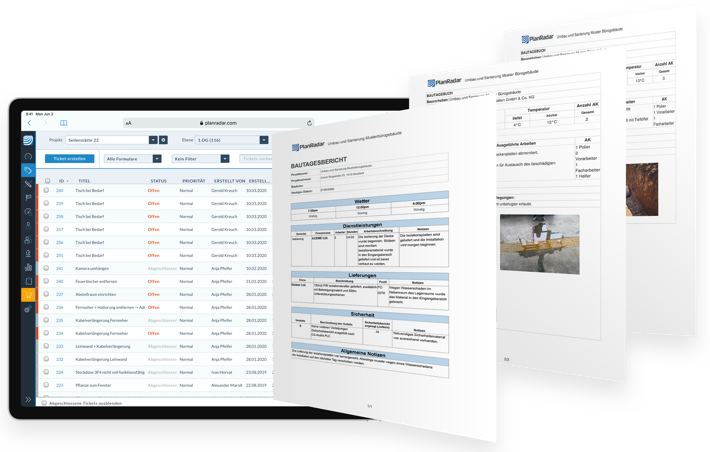

Digital safety walks replace ad-hoc inspections with structured workflows that ensure consistency across sites and teams. Standardised digital checklists guide inspectors through critical HSE items, ensuring nothing is overlooked—even when inspections are conducted by different individuals.

Inspections are completed directly from site using mobile devices. Mandatory fields reduce incomplete reports, while automatic time and user stamps improve traceability. Findings can be immediately converted into corrective actions, assigned to responsible parties, and tracked to closure.

This approach shifts safety walks from passive observations to active risk management—supporting real incident reduction rather than box-ticking exercises.

The Role of Evidence Capture in Reducing Incidents

Evidence capture is a critical component of effective digital safety walks. Photos and videos taken during inspections provide objective proof of site conditions at a specific point in time.

Unlike traditional methods, digital inspections link visual evidence directly to checklist items, locations, and corrective actions. This context is essential when reviewing incidents, responding to audits, or demonstrating compliance to authorities and clients.

For senior management and HSE leaders overseeing multiple sites, visual evidence also improves transparency and enables faster, more informed decision-making without relying solely on written summaries.

Example: Digital Safety Walk Checklist for GCC Projects

A typical digital safety walk checklist for GCC construction projects may include:

Site Access and Housekeeping: Clear walkways, controlled access points, safe storage of materials, and waste management.

PPE Compliance: Correct use of helmets, high-visibility clothing, gloves, eye protection, and safety footwear.

Working at Height: Condition of scaffolding, edge protection, harness usage, and permit validity.

Plant, Equipment, and Lifting Operations: Operator certification, equipment condition, exclusion zones, and lifting plans.

Fire Safety and Emergency Preparedness: Fire extinguishers, emergency access routes, signage, and assembly points.

Heat Stress Controls: Shaded rest areas, water availability, and compliance with local heat-related work regulations.

Each item is supported by photos, comments, and immediate task assignment, ensuring that identified risks are addressed—not just recorded.

Making HSE a Daily Discipline, Not a Periodic Activity

Improving safety outcomes on GCC construction sites requires more than scheduled safety walks. It requires consistent execution, reliable documentation, and accountability at every level of the project.

Digital safety walks enable HSE teams to embed safety into daily site operations. By capturing risks where work happens, documenting evidence in real time, and ensuring corrective actions are closed, projects can move from reactive safety management to proactive incident prevention.

For PlanRadar users operating across the GCC, digital safety walks provide a practical way to reduce incidents, strengthen compliance, and maintain clear oversight across even the most complex construction environments.

Start your free trial now and experience how digital safety walks can help improve HSE compliance and reduce incidents across your construction projects.