Rework rarely starts with a “big mistake.” More often, it begins with a small documentation gap that becomes expensive later: a photo with no location, a snag closed without evidence, a material delivery accepted without a quick condition check, or an inspection completed with unclear acceptance criteria.

Contractors feel the impact immediately. Crews return to areas that were “done.” Supervisors re-check items that should have been verified once. Subcontractors argue over responsibility because the record is incomplete. Meanwhile, schedules slip and costs climb.

The good news is that eliminating rework with digital documentation doesn’t require complicated processes. It requires a practical, repeatable system that captures the right information at the right time—using simple templates and consistent habits.

Below is a contractor-friendly approach built around four levers that reduce rework fast: photo documentation, task closure discipline, inspection templates, and material delivery logging.

Why rework happens (and where it usually hides)

When teams talk about rework, the conversation often lands on workmanship. However, on many sites, rework is driven by information failures that show up as physical work later.

Common root causes include:

- Outdated drawings and revisions being used on site because the latest version wasn’t clearly shared or referenced.

- Untracked change instructions (verbal or WhatsApp) that never become an approved site instruction or logged variation.

- Unclear handovers between trades, where one scope depends on another, but acceptance is assumed rather than confirmed.

- Missing approvals for materials, mock-ups, shop drawings, or inspections—so work is installed, then rejected.

- Tasks closed incorrectly, where the system says “done,” but the evidence and verification are missing.

Notice the pattern: rework starts when the project loses a single source of truth. That’s why eliminating rework with digital documentation is less about “more reporting” and more about “better capture.”

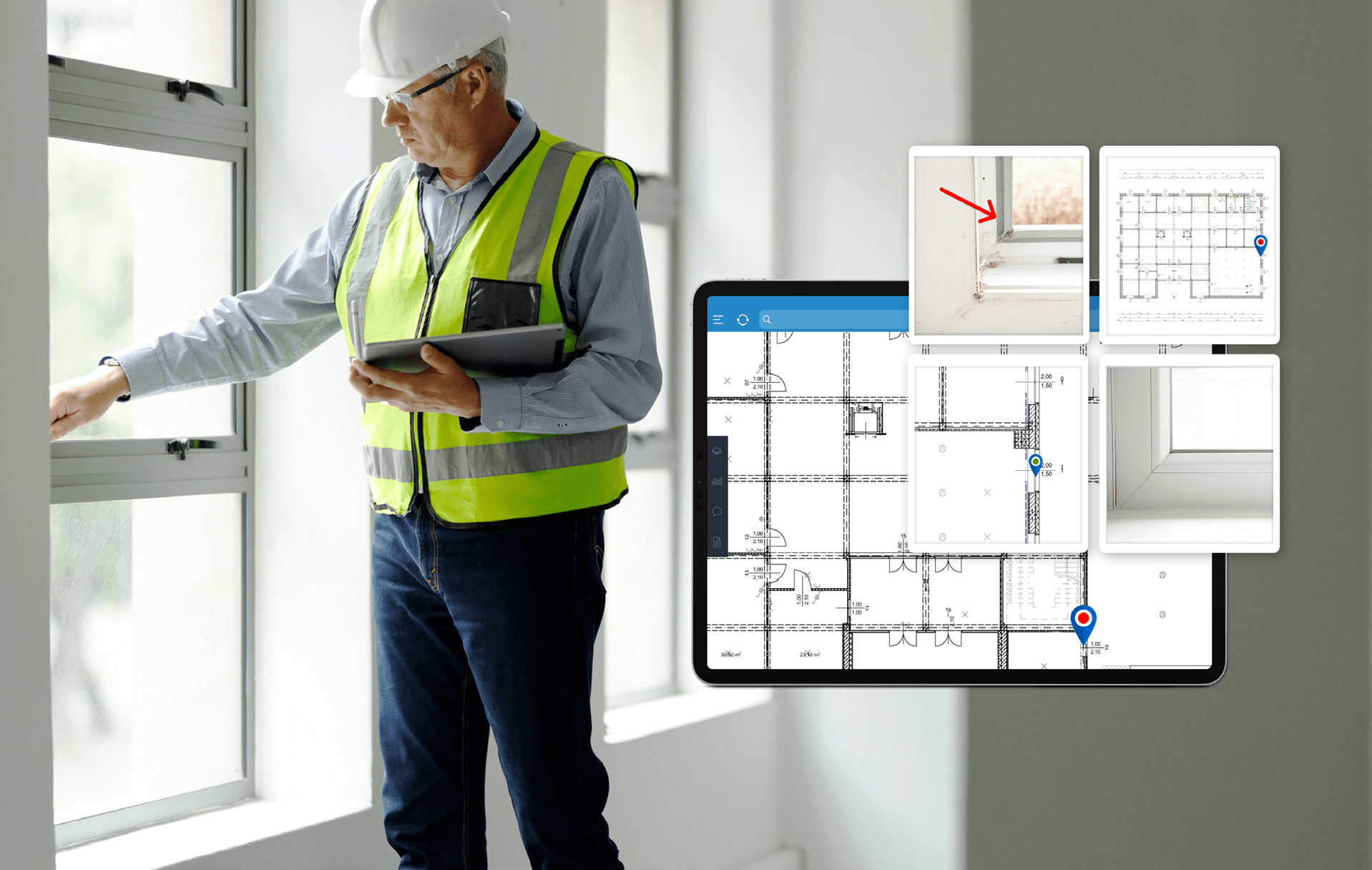

The hidden rework trigger: poor photo documentation

Photos are one of the most powerful anti-rework tools on a jobsite—if they are captured consistently and stored in a way that makes them usable later. Unfortunately, many sites collect thousands of photos that are effectively unusable because they lack context.

Here’s what typically goes wrong:

- Photos are saved in personal devices or chat threads.

- Photos have no location reference (floor/zone/room), so teams cannot find the right evidence quickly.

- Photos show the defect, but not the environmental context (wide shot), so the issue gets misinterpreted.

- “After” photos are missing, so closure is contested later.

- Photos aren’t linked to the relevant task, inspection, drawing pin, or package.

A practical photo standard contractors can adopt

A simple photo rule prevents most of these problems:

Every issue photo set should include three shots:

- Wide shot (shows the area and context)

- Close-up (shows the detail)

- Reference point (label, measurement, or identifiable marker)

Then add lightweight context:

- Location (level + zone/area)

- Trade and issue type (e.g., MEP / clearance, finishes / alignment)

- Status (before / after)

- Date/time (auto-captured helps)

This approach saves time later because supervisors stop “re-investigating” issues that already had proof. In practice, it’s one of the fastest ways to support eliminating rework with digital documentation.

Task closure mistakes that recreate the same problem

Many sites close tasks too early. The intention is good—keep dashboards clean and move forward. The result is rework, because teams return to “closed” items that were never properly verified.

Typical closure mistakes include:

- Closing snags without after-evidence (photo or verification note)

- Closing the main issue while dependencies remain open (e.g., firestopping not completed after MEP works)

- Closing tasks without confirming acceptance criteria (what “good” looks like)

- Closing without the right approver sign-off (client/consultant or internal QA)

The contractor-friendly “minimum closure pack”

To avoid rework, define a minimum standard for closure that is easy to follow:

- After photo (at least one clear shot, ideally the same angle as the “before”)

- Short closure note (what changed, who fixed it, and any relevant measurement)

- Inspection reference (if the task needs an inspection)

- Approver sign-off where required

A useful rule is: No evidence = not closed.

It sounds strict, but it prevents a lot of repeat work. More importantly, it makes accountability clear without arguments.

Inspection templates that prevent ambiguity

Inspections are where rework should be stopped early. Still, inspections often vary by supervisor, site, and trade. When acceptance criteria are unclear, defects slip through and reappear later as rework.

That’s why templates matter. A good inspection template does three things:

- Makes inspections consistent across supervisors

- Makes requirements unambiguous

- Makes evidence non-negotiable

What a strong inspection template includes

Keep templates simple, but structured:

- Clear pass/fail criteria (avoid vague wording like “OK”)

- Mandatory photo fields for critical checkpoints

- Notes field for measurements or test results

- NCR trigger logic (if failed, what happens next)

- Responsible party and due date

- Approval field (who signs off and when)

Start with templates that deliver quick impact

If you want immediate reduction in rework, prioritize high-risk, high-frequency scopes such as:

- Concrete works and pre-pour checks

- Waterproofing and wet areas

- MEP first-fix checks and pressure tests

- Firestopping and penetrations

- Finishing quality checks before handover

When inspections become repeatable and evidence-led, teams spend less time reopening the same issues. It also accelerates handovers because the record is complete.

Material delivery logging: prevent “install now, replace later”

Material-driven rework is painful because it often shows up late. The wrong material is delivered, stored incorrectly, or installed before it’s properly verified. Weeks later, it fails inspection—or worse, it fails in operation.

A lightweight delivery log reduces this risk significantly, especially when the log includes photos and approval status.

Minimum fields for a contractor-ready material log

You don’t need a complex system. Start with:

- Supplier and PO reference

- Material spec / model / rating

- Quantity delivered

- Batch/lot (for traceability, when relevant)

- Condition photos (packaging + close-up)

- Storage location on site

- Status: accepted / rejected / quarantined

- Related certificate or test reference (when applicable)

This makes it harder for incorrect or damaged materials to “slip into the build.” It also supports accountability with suppliers and subcontractors.

If your goal is eliminating rework with digital documentation, this is a high-leverage habit because it prevents rework before installation even happens.

A “minimum viable” digital documentation workflow for contractors

Contractors often avoid documentation initiatives because they worry about admin overload. The solution is a minimum viable workflow that fits real site pressure.

Here’s a practical cadence that works on most sites:

Daily (10 minutes per site lead)

- Progress photos for key zones

- Quick log of blockers or constraints (missing access, approvals, materials)

- Any high-risk issues opened as tasks with location + owner + due date

Per issue (when it happens)

- Create the task immediately

- Add “before” photo set (wide/close/reference)

- Pin to location / drawing zone if available

- Assign owner and target date

- Add closure pack when resolved

Per inspection (at defined checkpoints)

- Use a template checklist

- Capture evidence (mandatory photos)

- Record measurements/results if relevant

- Approve or fail with a clear next step

Weekly (short review)

- Review open issues by trade and zone

- Identify repeat causes (same defect type recurring)

- Confirm that closures include evidence

- Escalate blocked items with documented reasons

This workflow stays practical because it reduces re-checking, reduces disputes, and prevents repeated site visits to confirm basics.

Build a clean audit trail: accountability without conflict

A strong documentation system is not only about quality. It also reduces friction:

- Fewer arguments over “who caused it”

- Faster approvals because evidence is available

- Better subcontractor accountability (repeat issues become visible)

- Cleaner handovers because inspection and closure packs are complete

Use a simple audit-trail mindset for every key item:

Who did it → What was done → When it happened → Where it happened → Evidence → Approval

When this becomes routine, the project operates with less uncertainty. That is the operational backbone of eliminating rework with digital documentation.

Conclusion: reduce rework by standardizing the basics

Rework is expensive, but it’s often preventable. The biggest wins typically come from standardizing four fundamentals:

- Consistent photo documentation with context

- Correct task closure with evidence

- Inspection templates with clear acceptance criteria

- Material delivery logging with condition proof and approval status

Start small. Apply the system on one site or one trade package for two weeks. Measure the impact in reduced reopenings, fewer repeated snags, and faster approvals. Then scale it.

Because on live sites, the goal isn’t more documentation—it’s better decisions, fewer surprises, and fewer things built twice.