Why consistent inspections, structured IR/MIR workflows, and reliable documentation are critical for quality control at scale

Standardising QA/QC in construction is one of the biggest challenges facing large-scale developments today. As projects expand across multiple zones, contractors, and inspection teams, quality control processes often become inconsistent, fragmented, and difficult to manage.

In many GCC projects, QA/QC issues are not caused by missing standards, but by uneven execution across sites and phases. Without a consistent inspection approach, developers struggle to maintain visibility, traceability, and confidence in overall build quality.

Why QA/QC Inconsistencies Persist on Large Construction Projects

On large developments, multiple contractors and subcontractors often operate simultaneously across different zones, phases, or packages. Each party may bring its own inspection formats, reporting methods, and documentation habits. Over time, this leads to fragmented QA/QC practices.

Common issues include inspections carried out using different checklists, inconsistent defect classifications, and varying levels of detail in reports. In some cases, inspections are completed on paper and later transcribed, increasing the risk of missing information or delayed follow-up.

When QA/QC data is scattered across emails, spreadsheets, and standalone reports, project teams struggle to maintain a clear, real-time view of quality performance across the entire development.

Developer Expectations from Standardised QA/QC in Construction

From a developer’s perspective, quality control is not just about identifying defects—it is about demonstrating that consistent processes are being followed across all project phases.

Developers typically expect:

- Standardised inspection criteria across all contractors and packages

- Clear visibility into inspection status and outcomes

- Traceable records showing who inspected what, when, and against which standards

- Reliable documentation to support approvals, handovers, and future asset operations

In large-scale developments, where projects may span several years, inconsistent QA/QC execution creates long-term risks. Poor documentation at early stages often results in disputes, delays during handover, and incomplete asset records for operations and maintenance.

The Role of IR and MIR Workflows in Standardising QA/QC

Inspection Requests (IRs) and Material Inspection Requests (MIRs) form the backbone of QA/QC workflows on most large construction projects. However, when these workflows are managed manually or across disconnected systems, inefficiencies quickly emerge.

Typical challenges include unclear submission requirements, delayed approvals, lost inspection records, and limited visibility into inspection status. Contractors may resubmit incomplete requests, while consultants and developers spend valuable time chasing updates.

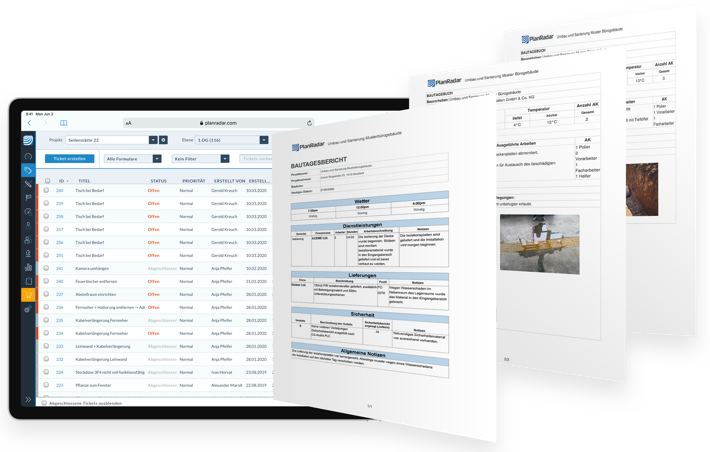

Standardised digital IR and MIR workflows help eliminate these bottlenecks by defining clear submission steps, required documentation, and approval paths. Requests can be reviewed, approved, rejected, or commented on within a single workflow, with every action recorded and time stamped.

This structure improves turnaround times and ensures that inspections are not just completed but completed correctly.

Understanding the QA/QC Inspection Cycle in Large-Scale Construction

In large-scale developments, QA/QC is not a one-off activity—it is a continuous cycle that must be managed consistently across all sites and phases.

A standardised inspection cycle typically includes:

- Pre-inspection preparation and checklist completion

- On-site inspection with documented observations

- Identification of non-conformances and required corrective actions

- Verification and re-inspection after corrective work

- Formal closure with documented approval

When this cycle is managed digitally, inspection status becomes transparent to all stakeholders. Project teams can quickly see which inspections are pending, which are under review, and which have been closed, reducing delays and miscommunication.

QA/QC Documentation Best Practices for Large Developments

Effective QA/QC documentation goes beyond storing inspection reports. Best practice focuses on creating a complete, structured quality record that supports the entire project lifecycle.

Key principles include:

- Using standardised digital templates for all inspections

- Capturing evidence (photos, comments, locations) directly during inspections

- Linking inspections to drawings, packages, or specific work areas

- Maintaining a central repository for all QA/QC records

- Ensuring records remain accessible after project completion

For developers managing multiple assets, this level of documentation provides long-term value. It supports smoother handovers, clearer defect liability management, and more efficient facility management operations.

From Fragmented Inspections to Standardising QA/QC in Construction

Standardising QA/QC across large-scale developments is less about introducing new standards and more about ensuring consistent execution. When inspection workflows, IR/MIR processes, and documentation practices are aligned, quality control becomes measurable, transparent, and repeatable.

For GCC developers and project teams operating at scale, structured QA/QC workflows help reduce rework, minimise disputes, and maintain confidence that quality expectations are being met across every site and phase.

Consistent quality starts with consistent processes. Standardised QA/QC workflows help project teams maintain control, reduce risk, and deliver large-scale developments with confidence.

Get practical insights into how standardised QA/QC workflows improve inspection consistency, reduce rework, and strengthen quality control across large-scale construction projects.