The GCC’s construction sector is undergoing a digital revolution — yet one critical process is still catching up: Digital QAQC in Construction.

While most companies have embraced digital tools for design and planning, many still depend on paper checklists, Excel sheets, and email threads to manage quality assurance and control.

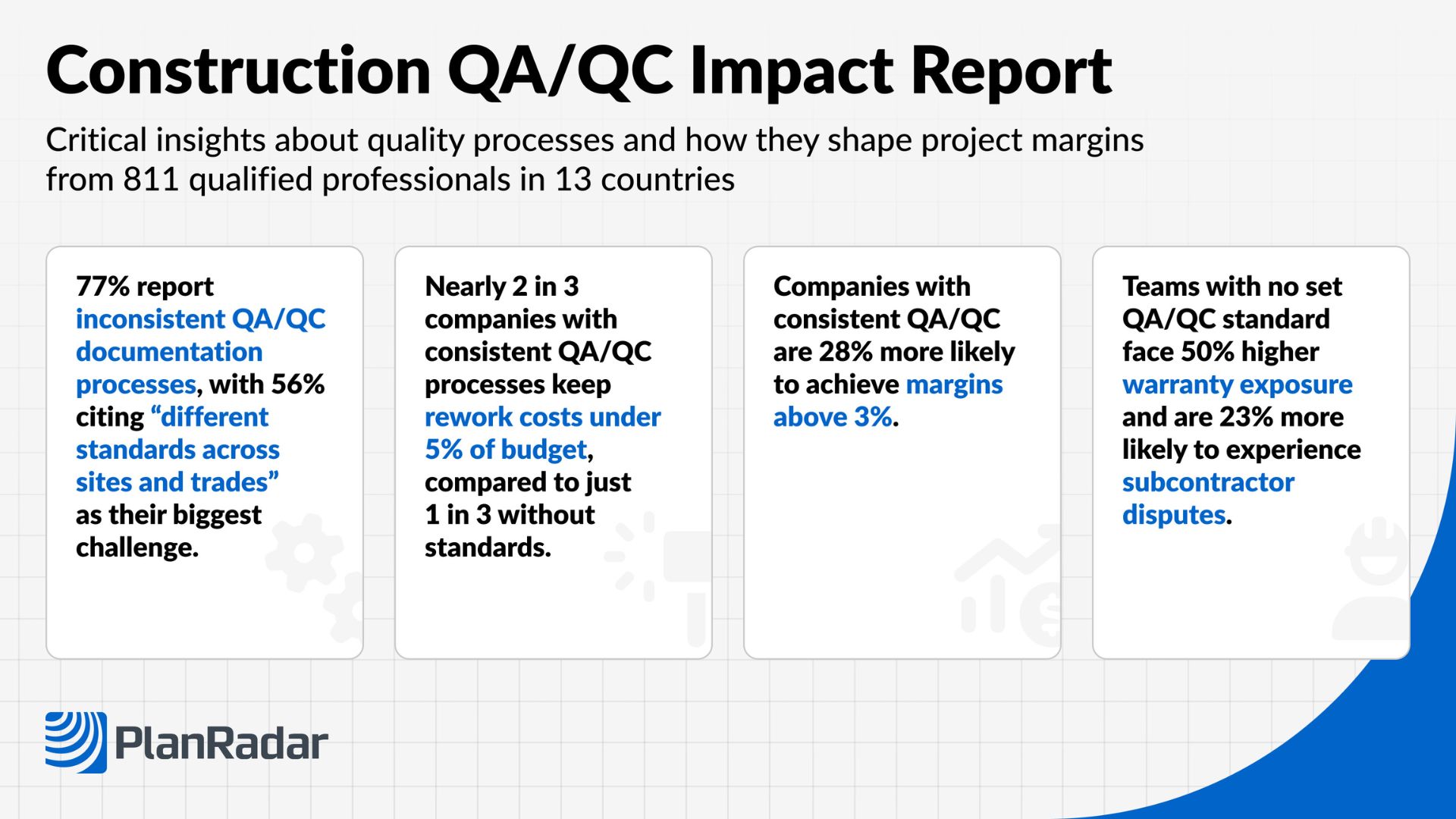

According to PlanRadar’s Construction QA/QC Impact Report, 67% of companies still rely on manual QA/QC methods, creating inconsistencies that cost both time and profit.

This article explores how GCC firms are replacing outdated documentation with Digital QAQC in Construction platforms that ensure accuracy, transparency, and control.

Why Paper-Based QA/QC Holds Construction Projects Back

Despite the region’s focus on smart cities and digital transformation, many construction teams still manage inspections manually. Paper workflows slow communication, delay sign-offs, and make it difficult to track accountability — the very reasons Digital QAQC in Construction has become a priority for forward-thinking companies.

According to the QA/QC Impact Report:

- 77% of companies report inconsistent QA/QC documentation.

- Missing or late inspection records often lead to costly rework and disputes.

Without a unified system, managers can’t easily see what was done, when, and by whom — and that’s where digital QA/QC platforms make the difference.

Read more about how inconsistent QA/QC impacts profitability in our previous blog post

Why the GCC Is Ready for Digital QA/QC Transformation

The GCC region is uniquely positioned to lead this shift. With national visions like Saudi Vision 2030 and the UAE Digital Government Strategy, public and private developers alike are pushing for paperless workflows and transparent data-sharing across project stages. In this environment, Digital QA/QC in Construction is no longer optional — it’s an essential pillar of compliance, efficiency, and sustainability.

According to PlanRadar’s GCC Construction Insights 2025, digitization is among the top five priorities for regional construction executives. Developers and government bodies are increasingly requiring contractors to use digital documentation for quality audits, approvals, and reporting. Digital transformation has moved from being a competitive advantage to a project requirement.

From Fragmented Tools to Unified Digital QA/QC Platforms

Many construction firms in the GCC currently juggle multiple disconnected tools — WhatsApp for photos, Excel for punch lists, email for approvals, and PDFs for reports. This fragmented approach slows down collaboration and leaves room for error.

The solution lies in unified digital platforms that consolidate all QA/QC data into one accessible source.

A digital QA/QC system centralizes information, allowing:

- Field teams to record data directly on-site using mobile apps.

- Instant access to real-time dashboards and updates for managers.

- Automatically generated, audit-ready reports.

The QA/QC Impact Report found that companies with consistent QA/QC are 5.6× more likely to be using a single site-based platform from early project stages. This integration not only improves quality tracking but also builds a verifiable trail of accountability.

To learn how PlanRadar supports unified quality workflows, visit our QA Educations webpage.

The Measurable Benefits of Digital QA/QC

Transitioning from paper to platform brings measurable results that go beyond convenience.

Companies that digitize their QA/QC processes report higher productivity, better collaboration, and improved profitability.

According to the QA/QC Impact Report:

- Two in three companies with consistent QA/QC keep rework costs under 5% of total project budget.

- Firms without QA/QC standards are 50% more likely to face warranty claims and 23% more likely to experience subcontractor disputes.

These findings align with global studies like McKinsey’s Reimagining Construction, which found that digital tools can improve productivity by up to 15% and reduce project costs by up to 20%.

Other key benefits include:

- Reduced rework and waste: Digital QA/QC ensures errors are caught early.

- Faster approvals: Automated workflows accelerate sign-offs and handovers.

- Data-driven decisions: Dashboards highlight recurring defects and performance gaps.

- Regulatory compliance: Standardized records simplify audits and warranty reviews.

The Road Ahead — Making Digital QA/QC the New Standard

As GCC construction continues to evolve, Digital QA/QC in Construction is becoming a defining benchmark of operational excellence. Yet challenges remain resistance to change, lack of staff training, and integration across legacy systems.

The key is to view digitization not as an IT upgrade, but as a process transformation. By embedding QA/QC workflows into one platform, companies can:

- Eliminate data silos.

- Ensure every inspection, issue, and photo is logged consistently.

- Access real-time insights that strengthen decision-making.

Over time, this shift builds a culture of transparency and continuous improvement — one that reduces risk and boosts profitability across every project. The GCC market is ready, and the data is clear: firms that embrace digital QA/QC now will set tomorrow’s standards for quality, efficiency, and trust.

Conclusion

The construction industry’s next leap in efficiency won’t come from working harder — but from working smarter.

The Construction QA/QC Impact Report proves that digitizing QA/QC documentation is one of the fastest, most effective ways to improve consistency, reduce costs, and strengthen project margins.

📘 Download the full report to explore real data on how digital QA/QC platforms are shaping the future of construction quality across the GCC.