In the GCC’s fast paced and highly competitive construction sector, QAQC in Construction has become a decisive factor in project success. Across the UAE, Saudi Arabia, Qatar, Kuwait, Oman, and Bahrain, developers and contractors increasingly recognize that quality assurance and control are not just technical requirements — they are essential to maintaining profitability and client trust.

However, despite heavy investment in inspection teams and compliance frameworks, many firms still face one persistent challenge: inconsistency in QAQC in Construction across sites, trades, and subcontractors.

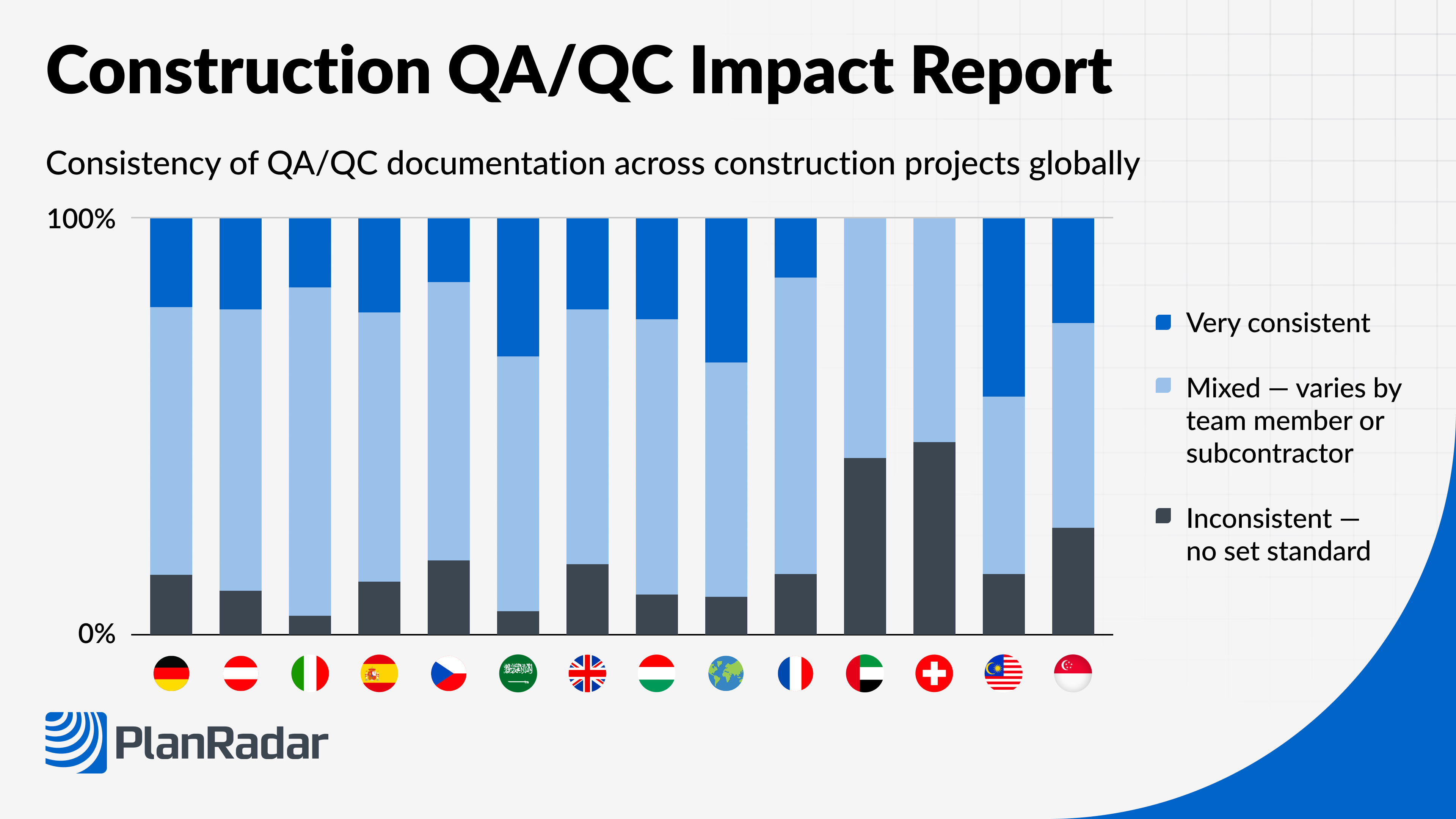

According to PlanRadar’s latest Construction QA/QC Impact Report, built from insights from over 800 professionals globally (including the GCC), more than 70% of companies begin QA/QC processes from day one, yet 77% still report inconsistencies in their documentation and implementation. This inconsistency creates what the report calls “the QA/QC lottery,” where project quality depends more on who is on-site than on a defined standard.

Early Planning Is Not Enough

Most GCC firms understand that quality starts from day one. Yet, QAQC in Construction isn’t only about timing — it’s about structure and enforcement. The data shows that while early QA/QC planning is common, only 15% of firms that start early experience fewer rework or delay issues.

The reason is simple: without consistent application, even the best QA/QC plans lose effectiveness. In practice, fragmented documentation, varied subcontractor standards, and unclear accountability dilute outcomes. In markets like Saudi Arabia and the UAE, where mega-projects and tight handover schedules are the norm, such inconsistencies in QAQC in Construction can significantly inflate costs and erode margins.

The Hidden Cost of QAQC Inconsistency

The Construction QA/QC Impact Report makes one thing clear — QAQC in Construction directly affects profitability.

Companies with consistent QA/QC standards are 28% more likely to achieve profit margins above 3%, while those with no standards face a 50% higher risk of warranty exposure and are 23% more likely to have subcontractor disputes.

Even more concerning, nearly half of companies without QA/QC standards admit they have no visibility into rework costs. By contrast, two in three companies with consistent QAQC in Construction keep rework below 5% of project budgets — a remarkable cost advantage in a region where projects can exceed billions in value.

These findings align with a broader global pattern: poor construction quality can account for up to 15–25% of total project costs, according to a study by AuditCo. Similarly, Autodesk Construction Cloud reports that over 60% of contractors worldwide say poor QAQC processes significantly impact their profitability.

The Domino Effect of Poor QAQC in Construction

When QAQC in Construction fails, the consequences cascade through the project lifecycle. Two-thirds of companies (67%) report project delays due to poor QA/QC practices, with over half stating those delays exceed two weeks. Nearly a quarter face month-long disruption.

These time losses lead to compounding costs:

- Rising labour and overtime costs — 76% of companies face increased staffing expenses to recover lost time.

- Strained client relationships — 50% report damaged trust with clients following quality-related delays.

- Contractual penalties — 32% incur financial penalties for missing deadlines.

In a region where deadlines are tied to government milestones like Saudi Vision 2030 and the UAE’s infrastructure expansion, poor QAQC in Construction becomes not just a technical issue but a strategic risk to company reputation and long-term profitability.

Why QAQC Inconsistency Persists

If so many companies see the value of QAQC in Construction, why does inconsistency remain?

PlanRadar’s study identifies three root causes:

- Fragmented subcontractor management — multiple subcontractors often apply their own QA/QC methods, leading to variability.

- Lack of unified digital tools — only 28% of firms use a single site-based digital platform for QA/QC; most still rely on spreadsheets and paper.

- Weak enforcement — while 45% claim to “enforce” QA/QC through forms or digital tools, 65% admit standards still vary across projects.

According to PlanRadar’s GCC Industry Insights 2025, nearly 60% of regional firms plan to expand their digital QAQC in Construction capabilities by 2026. This shows recognition that technology is essential — but effective only when paired with consistent processes.

Turning QAQC in Construction into a Profit Strategy

The strongest message from the report is that QAQC in Construction is not just about compliance — it’s a profit driver.

More than 78% of companies believe stronger QA/QC processes can improve profitability, and over one-third have already experienced measurable financial benefits after implementing systematic QA/QC frameworks.

GCC leaders can turn QAQC in Construction into a competitive advantage by:

- Defining a single QA/QC standard that aligns all subcontractors and trades.

- Digitising processes to ensure every inspection, issue, and sign-off is tracked consistently.

- Measuring quality performance using KPIs such as defect rates and rework costs (PlanRadar KPIs Guide).

Unified QAQC in Construction ensures accountability, reduces risk, and creates a data-driven foundation for continuous improvement — all of which directly impact profitability.

A Path Forward for GCC Construction Leaders

As construction across the GCC continues to grow at a rapid pace, the need for consistent QAQC in Construction will only increase. The key lies in adopting one enforceable standard, supported by the right digital infrastructure.

By integrating QAQC into every stage of project delivery — from initial planning to handover — companies can replace reactive quality checks with proactive assurance. The result: fewer disputes, lower rework, stronger margins, and better client relationships.

To stay competitive in the evolving GCC landscape, construction leaders must move beyond fragmented practices and embed QAQC in Construction as a cultural and operational standard.

Download the full Construction QA/QC Impact Report

Explore detailed data and practical insights on how consistent QAQC in Construction can improve profitability, reduce risk, and ensure project quality across the GCC.