Rework in construction is one of the industry’s most persistent and expensive challenges. Decades of construction rework studies show that fixing mistakes consumes 5–10% of total project costs—and sometimes far more. This article summarizes key findings on the cost of rework in construction, the main causes of rework, and how consistent QA/QC processes can dramatically reduce its impact.

Cost of Rework in Construction Projects

Academic and industry research consistently shows that rework represents one of the most significant hidden costs in construction. Across project types and regions, rework accounts for 1–20% of total project cost, with most studies clustering between 4–10%. The Construction Industry Institute (CII) and multiple peer-reviewed studies confirm that even modest percentages translate to billions in lost project value globally.

The table below summarizes findings from multiple construction rework studies on cost percentages published between 1991 and 2024.

| Rework Cost (% of Total Project Cost) | Project Type / Scope | Source |

| 10–20% | General | Cnudde (1991) |

| 10% | Civic / General | Nylén (1996) |

| 2.77% (avg.) | General | Love & Li (2000) |

| 5.0% (avg.) | General | Hwang et al. (2009) |

| 5.06% (avg.) | General | Oyewobi et al. (2011) |

| 2–20% (range) | General | CII (2011) |

| 6.44% (avg.) | General | McDonald (2013) |

| 4.9% | General | Dougherty & Hughes (2014) |

| 4.95% (avg.) | Residential | Liu et al. (2018) |

| 0.39% (mean) | General (production phase only) | Love et al. (2019) |

| 0.81% (avg.) | General | Singh et al. (2022) |

| 7.9% | General | PlanRadar (2023 |

| 5–10% | Residential | Mahamid (2024) |

Key takeaways:

1️⃣ Since the 1990s, the cost of rework as a percentage of total project cost has declined from double-digit figures to around 5-8% — a shift largely attributed to the adoption of digital QA/QC systems, improved communication tools, and better project controls.

2️⃣ Even at the lower end of current estimates (~5% of total project cost), rework represents a significant profit risk — equivalent to several percentage points of contractor margin on a typical project.

Causes for Rework in Construction Projects

Academic studies consistently show that design-related errors and deviations account for 1–9% of total project cost. These include design omissions, inaccurate drawings, and late design changes.

| Rework cost due to design-related errors (% of Total Project Cost) | Project Type / Scope | Source |

| 6.9% | General | Cnudde (1991) |

| 9.5% | Industrial | Burati et al. (1992) |

| 1.8% | General | Hwang et al. (2009) |

| 1.5% | General | Dougherty & Hughes (2014) |

Construction-related causes — such as workmanship errors, deviations from plans, and improper supervision — contribute a smaller but still significant share, up to 3% of total project cost in industrial and building projects.

| Rework cost due to construction-related causes (% of Total Project Cost) | Project Type / Scope | Source |

| 3.3% | General | Cnudde (1991) |

| 2.5% | Industrial | Burati et al. (1992) |

| 0.3% | General | Dougherty & Hughes (2014) |

Key takeaways:

1️⃣ Since the early 1990s, the cost impact of design-related errors has fallen from around 9% to just 1–2% of total project cost, reflecting the positive effects of digitisation, BIM adoption, and improved design coordination workflows across the construction sector. Nonetheless, strengthening early-stage coordination and design verification offers a high leverage for reducing rework.

2️⃣ Because of the scarcity of empirical studies, the financial impact of construction-related errors on project costs cannot yet be quantified with confidence.

Underlying Information-Related Factors Driving Rework

While design and construction errors are the most visible causes of rework, research shows that these problems often originate from deeper information-related issues.

Studies find that miscommunication causes 26% of all rework while bad data or inaccurate information causes 14-22% of all rework.

| Underlying Factor | Share of Total Rework (%) | Project Type / Scope | Source |

| Miscommunication | 26% | General | PlanGrid & FMI (2018) |

| Bad / inaccurate data or information | 22% | General | PlanGrid & FMI (2018) |

| Bad data | 14% | General | Autodesk & FMI (2021) |

The Impact of QA/QC on Rework

PlanRadar’s Construction QA/QC Impact Report 2025 provides new evidence showing how consistent quality management directly reduces rework costs and protects profit margins. Across 811 professionals surveyed across 13 countries, the data shows that rework is not just a technical failure — it’s a management and process issue, strongly correlated with the consistency of QA/QC practices.

💰 Nearly two in three companies (56%) with consistent QA/QC processes keep rework costs under 5% of project budget, compared with only one in three (37%) without standards.

⚠️ Firms without QA/QC standards are 21% more likely to experience avoidable rework, 50% more likely to face warranty exposure, and 23% more likely to have subcontractor disputes.

📈 Consistency also correlates with profitability: companies with strong QA/QC standards are 25–28% more likely to achieve profit margins above 3%.

These findings confirm that consistent QA/QC practices are one of the most effective ways to reduce rework in construction, bringing down both direct costs and project delays.

How PlanRadar Helps Reduce Rework with Consistent QA/QC

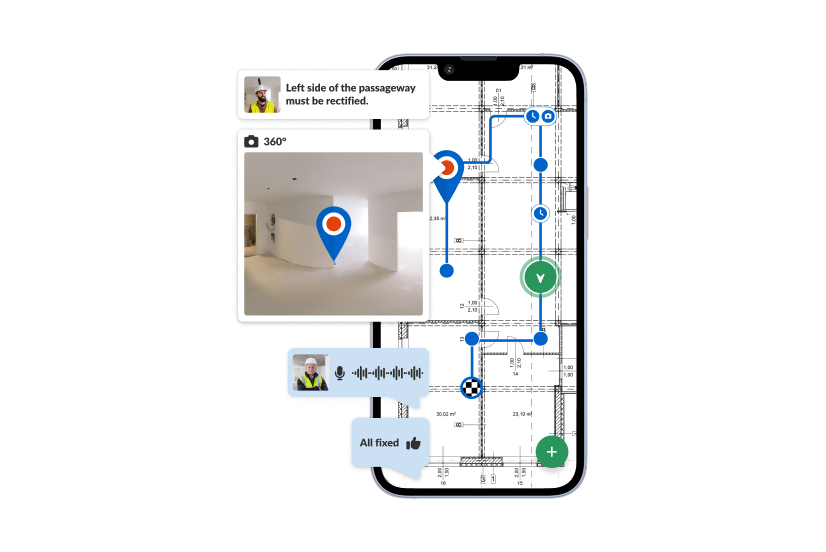

PlanRadar is a platform for digital documentation, communication, and reporting in construction and real estate projects. With PlanRadar, QA/QC goes beyond checklists. It standardizes how teams capture, verify, and act on quality data—cutting rework, preventing disputes, and protecting margins.

✅ Flexible QA/QC workflows: Create digital checklists, inspection forms, and approval steps tailored to each project and trade, ensuring every process follows the same standard.

✅ Clear subcontractor accountability: Centralize all QA/QC data, comments, and sign-offs so every contractor knows what’s required—no missed checks or duplicated work.

✅ Always available on site: Use the mobile app online or offline to record inspections, attach photos, and close issues; everything syncs automatically when connectivity returns.

✅ Simple to adopt: With an intuitive interface, teams can start capturing QA/QC data within minutes—no complex setup or long training sessions required.

👉 Ready to reduce rework and improve quality consistency? Book a free demo today and see how PlanRadar supports systematic QA/QC on every project.