Standardisation is the holy grail of quality management in construction. Whether you’re delivering five housing developments, maintaining hundreds of social housing units, or managing fit-out projects across the UK, consistent inspection templates promise fewer mistakes, cleaner data, and faster reporting.

But here’s the catch: standardising inspection templates across multiple sites is far harder than it sounds. Every project is different. Site conditions vary, trades have their own workflows, and client requirements constantly evolve. What looks perfect in a spreadsheet or head office policy document often breaks down once boots hit the ground.

Why Standardisation Matters

When inspection processes are standardised, every project starts from the same playbook. QA/QC teams can rely on consistent checklists, meaning no missing steps, no forgotten forms, and fewer disputes later on.

For construction firms, the benefits are clear:

- Data consistency – Comparable inspection data across all projects enables benchmarking and performance tracking.

- Compliance confidence – A standardised approach makes it easier to prove adherence to regulations such as the Building Safety Act or Future Homes Standard.

- Efficiency at scale – Templates save time on setup and onboarding, particularly for teams managing dozens of projects.

- Continuous improvement – When inspection data is uniform, it’s far easier to spot recurring quality issues and fix them at source.

In short, standardisation isn’t just about tidier documentation – it’s about smarter decision-making, faster builds, and stronger compliance.

The Reality: Why It’s Harder Than It Sounds

Achieving this consistency sounds simple on paper. In practice, construction projects are messy, dynamic environments. Here are the most common barriers companies face:

- Different Projects, Different Risks

A high-rise apartment block doesn’t face the same risks as a row of townhouses or a hospital refurbishment. Each requires its own inspection focus – from fire safety and M&E commissioning to airtightness and snagging. A single “universal” template rarely fits all, and adapting it manually can introduce inconsistencies.

- Subcontractor Variations

Even within one organisation, different subcontractors often use different QA processes. One may prefer detailed photographic evidence; another might only record pass/fail results. Without a unified system, gathering consistent data becomes a constant uphill battle.

- Changing Regulations

UK construction is experiencing one of its most significant regulatory overhauls in decades. The Building Safety Act, updates to Part L, and the upcoming Future Homes Standard are forcing companies to refresh their inspection checklists regularly. Standardisation becomes a moving target, with templates needing near-constant revision to stay compliant.

- Outdated Tools

Many teams still rely on static Excel sheets, Word documents, or PDF forms to manage inspections. These formats aren’t built for collaboration or version control. Before long, multiple “final” versions exist across different teams – and the audit trail is lost.

- Human Behaviour

Even with the best intentions, site teams often adapt templates to suit how they work. They might add custom fields, skip steps, or rename sections to make sense locally. While these tweaks can improve practicality on one site, they create fragmentation across the business.

The Cost of Inconsistency

When templates vary, the consequences ripple through every part of the project. A missing field or an inconsistent naming convention might seem small, but it can break reporting systems, compromise audit trails, and introduce risk.

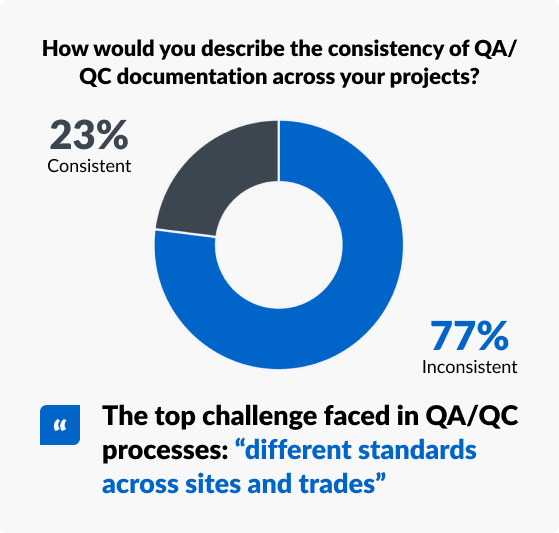

In PlanRadar’s 2024 QA/QC Report, 75% of UK respondents said inconsistent or delayed QA data caused project delays or lost time. For many, this means missed deadlines, client disputes, or even rework – all avoidable if inspections were standardised and centralised.

Inconsistent data doesn’t just waste time. It erodes confidence – both internally and with clients and regulators. When teams can’t trust the information they’re reviewing, decisions slow down and accountability weakens.

How Technology Can Help

Digital platforms like PlanRadar are making standardisation achievable – without the rigidity that used to come with it.

Here’s how modern inspection software helps organisations regain control:

- Central template library: Create a single, master version of each inspection type – from snagging and fire door checks to M&E or QA/QC inspections – and roll it out company-wide.

- Controlled flexibility: Allow head office to lock down key fields while giving site teams limited flexibility to add context-specific details. This balance ensures consistency without stifling practicality.

- Real-time updates: When standards or regulations change, teams can update a template once and automatically deploy the new version across all active projects.

- Tamper-proof audit trail: Every inspection, comment, and sign-off is logged automatically, giving full traceability for compliance or dispute resolution.

- Integration and automation: With PlanRadar Connect, inspection data can flow seamlessly into platforms like Power BI, SharePoint or custom dashboards for company-wide reporting.

Instead of juggling spreadsheets, project teams work from a live digital template that evolves with the business. Consistency becomes built-in, not an afterthought.

Standardisation as a Journey

True standardisation isn’t about enforcing identical templates on every project. It’s about finding the right balance between consistency and adaptability.

Digital inspection tools make that balance possible. With a shared library, controlled permissions, and live reporting, companies can maintain high standards across every project while empowering teams to respond to real-world conditions on site.

The result? Better data, faster inspections, and stronger compliance — no matter how many sites you manage.