In construction, quality control has traditionally been reactive. Defects are spotted during inspections, flagged for correction, and then fixed — often after they’ve already caused costly delays or reputational damage.

But what if those issues could be identified before they ever appear on-site?

Today, digital inspection tools are turning this idea into reality. By collecting and analysing inspection data across multiple projects, forward-thinking contractors, housebuilders and fit-out firms are beginning to predict where problems are likely to arise — and take preventative action early. The result? Better quality, reduced rework, and stronger client trust.

From Reactive to Predictive Construction

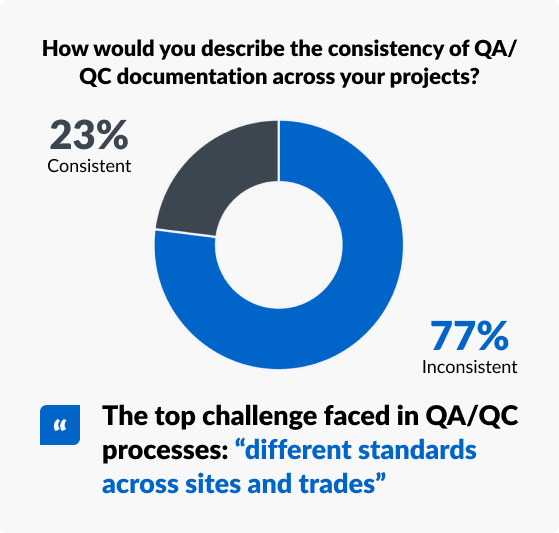

Quality assurance (QA) and quality control (QC) are vital in every construction project. Yet many teams still treat inspections as a checklist exercise — a snapshot in time, rather than an ongoing source of intelligence.

Every inspection creates valuable data: the type of issue found, its location, which trade was involved, how long it took to resolve, and what stage of the build it occurred at. When captured digitally, this information becomes the foundation for a new approach — one that uses past trends to prevent future defects. Predictive quality management doesn’t replace human expertise. Instead, it enhances it. By recognising patterns early, teams can deploy training, improve materials handling, or adjust sequencing before a defect reappears.

The Untapped Value of Inspection Data

Every snag logged or issue reported is a data point. On its own, it might seem insignificant. But aggregated across dozens of projects, inspection data reveals the recurring pain points that eat into margins and timelines.

For example:

- Recurring snag types – If the same problem appears repeatedly (for instance, door misalignments or firestopping inconsistencies), it may indicate a process or training gap.

- Timing analysis – Long resolution times might signal bottlenecks in communication or unclear accountability.

- Trade performance – Tracking defects by subcontractor or discipline helps identify where extra supervision or coaching is needed.

- Location heatmaps – When mapped to floor plans or 360° captures, inspection data can highlight “hot spots” that are prone to error, enabling teams to pre-empt similar issues elsewhere.

In other words, inspection data transforms guesswork into foresight. Rather than waiting for something to go wrong, teams can predict where problems are most likely to occur and take steps to prevent them.

Spotting Patterns That Predict Problems

The ability to spot patterns across projects is where digital QA/QC software truly shines. Predictive analytics can identify root causes, recurring defects, and correlations that might not be visible to even the most experienced project manager.

Examples of Predictive Quality in Action

- Analysing trends to anticipate when certain trades or materials are most likely to cause defects.

- Comparing performance data across projects to pinpoint process weaknesses.

- Forecasting risk levels for upcoming project stages based on historical defect data.

When construction teams have access to this insight, prevention becomes part of everyday operations — not a post-mortem exercise.

From Data Collection to Predictive Insight

Collecting inspection data is only the beginning. With PlanRadar’s Project Analysis & Insights, that data becomes a living, actionable intelligence engine that supports proactive decision-making on every project.

Each defect or issue logged in PlanRadar carries critical metadata—photos, timestamps, location, priority, and responsible party. But the true value lies in how Project Analysis & Insights transforms this into real-time dashboards and reports, allowing you to:

-

View, segment, and export AI-enhanced project data at any time. No more waiting for weekly reports—get access to up-to-date information from any device.

-

Trust unfiltered, tamperproof data. Every record is time- and date-stamped and stored in an immutable way, so what you see is always the ground truth.

-

Skip the delays of manual reporting. Project stakeholders can monitor progress continuously—no more waiting for site teams to compile summaries.

-

Generate flexible, custom insights. Whether you want high-level overviews or detailed drill-downs, you can adapt reporting to what matters most for your team.

What this means in practice: as inspection data accumulates across your project portfolio, patterns begin to emerge. You’ll see which defect types are rising, which areas of a build are hot-spots for failure, and which trade packages need more supervision. That insight allows site and project leads to anticipate risk, brief teams proactively, and direct resources before defects spiral.

By elevating your data from passive records into predictive signals, PlanRadar’s Project Analysis & Insights bridges the gap between doing inspections and thinking ahead.

The Business Case for Predictive Quality

Rework is one of construction’s biggest hidden costs. Studies suggest it can consume up to 5% of total project value and cause weeks of delay — all while eroding profit margins and client confidence.

Tangible Benefits of Predictive QA/QC

- Fewer repeat defects and reduced rework.

- Stronger client relationships built on consistency and reliability.

- Lower project costs and faster handovers.

- Better data visibility across entire portfolios.

Predictive quality management makes those outcomes achievable. When inspection data highlights risks before they materialise, teams save time, reduce waste, and avoid disputes, while delivering higher-quality projects on the first attempt.

The Future of QA/QC Is Predictive

The construction industry is evolving rapidly. As digital tools become standard, inspection data will no longer be something stored and forgotten — it will be an active part of project intelligence.

Platforms like PlanRadar make that shift accessible today. When every inspection becomes a data point, and every data point drives smarter decisions, quality stops being a box to tick and becomes a measurable, proactive process.

Predicting defects before they happen isn’t just about technology; it’s about building better from the ground up.

Take out a free 30-day trial to give the app a go and see for yourself how easy it is to start getting better data.